- Newell manufactures air and hydraulic compression stations to be used with side seal Signode strapping machines. These units have been used for compressing corrugated material, lumber, veneer, rolls of straw, textiles, and two piece cartons with compressible materials. Any item requiring compression for load integrity or reduced load volume can be a candidate for these machines. Each unit is designed around the customer’s requirements, with air used up to 4,000# compression and hydraulic up to 24,000# compression.

- The Newell Single Strap Compressor is designed to fit on either side of a side seal Signode strapping machine, to compress a load while in the strapping machine. These units are used with Signode MCD-710's, SP-710's, Suretyer's, PSF-2 power strap feeders, and the newer MOD-710's.

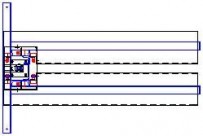

- The Newell Dual Strap Compressor was originally designed for plastic pallets of yarn, but have been used since then for corrugated plants, two piece cartons, and foam. The unit has integral Newell 2000 Series or Newell 2005 Series conveyor with slots for the Signode side seal strapping machines. They include an integral air operated pusher with back stop.

- We have built and installed up to four automatic Signode strapping machines into our compressors, with up to 24,000# compression.

- Available with Signode top sealing heads and pallet void feeding devices (PVFA's).